Capacity

Physically, mentally and financially

Imagine an area of 8000 m2 in the middle of Uddevalla’s old shipbuilding industry, where passionate employees at all levels deliver, day in and day out. At UFAB, we breathe our brand promise “Always Improve”. We are convinced that our promise improves not only your product, but also our work environment. A good and safe working environment creates good conditions for development and success, something we clearly see in our finished products.

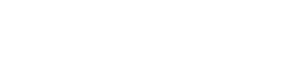

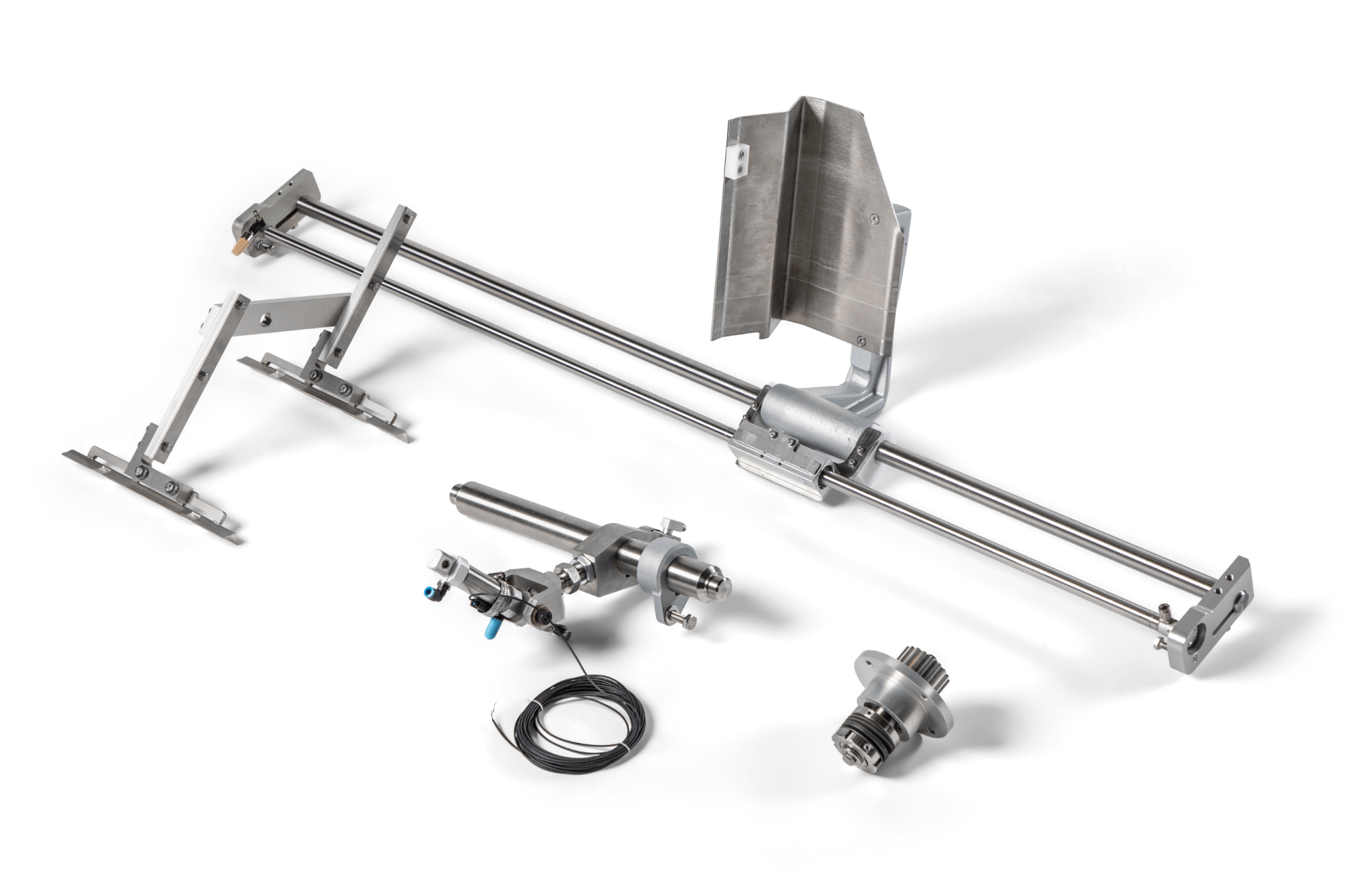

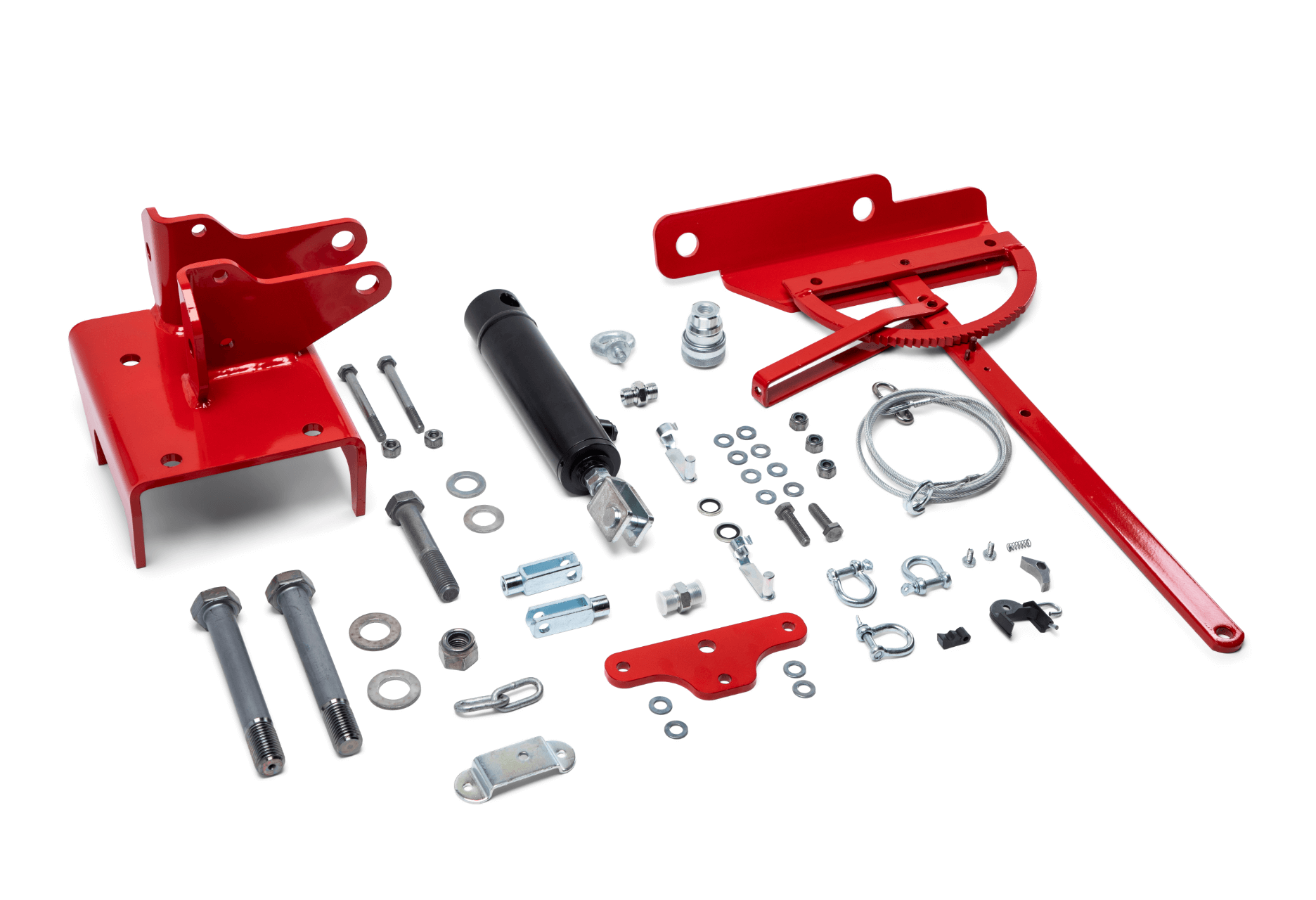

Our 40 assembly technicians keep the large assembly surface clean and tidy. We more than welcome visitors to the facility. We’re soon-to-be proud owners of a clean room that gives us maximum control over the level of airborne particles, temperature, relative humidity, air flow and differentiated pressure. All to give our employees the best possible conditions to succeed with your product.

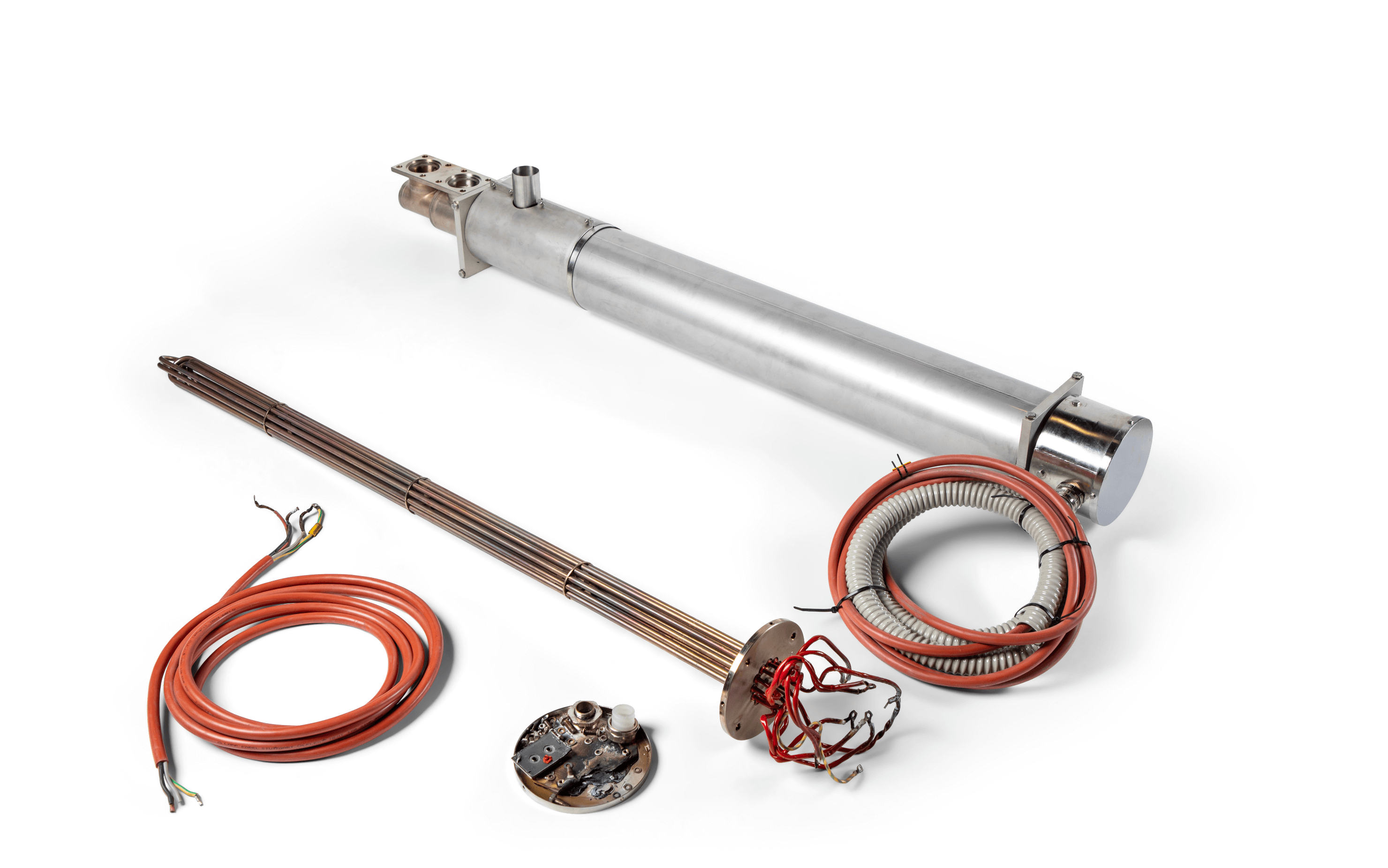

At UFAB, we are with you all the way, from idea to assembly, and beyond. We have the ability to lift your idea, and the capacity to lift up to 20 tons. When your units need to be overhauled, UFAB can once again be of assistance. We assist with service and renovation to ensure that the life of your components is extended. A service that benefits you, us and the environment.

As a company in the Mattsson Group, UFAB has a stable platform to operate from, which means that we can take on large assignments for customers who require working capital.

In short, UFAB has the capacity: physically, mentally and financially.